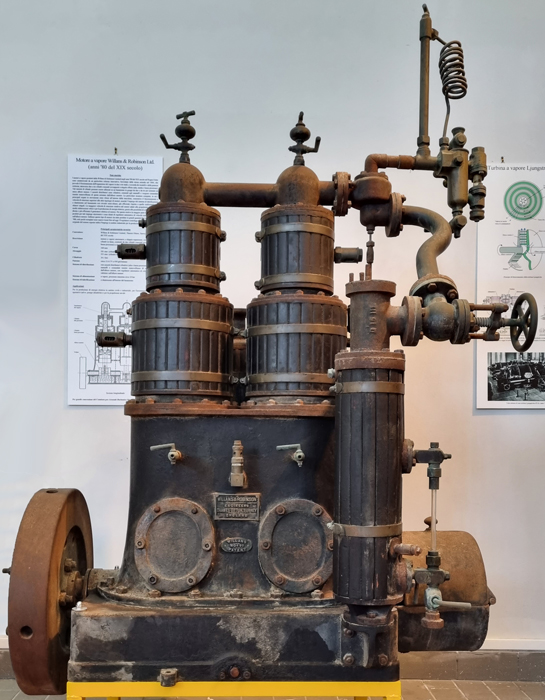

Willans & Robinson Limited was an important and prolific UK company specialised in the construction of industrial and marine engines. Its production was characterized by the use of a particular innovative scheme, patented by the same company in 1884, in which the steam expansion is divided into two or three stages using coaxial cylinders (high, medium and low pressure respectively). These sets of cylinders were aligned in groups of two or three on a common crankcase. Both inlet and discharge of the steam is governed by means of cylindrical distributors, coaxial to the pistons. Its particular and compact structure, in which the main moving parts are located inside the crankcase, allowed a better lubrication and, therefore, higher rotation speeds than other types of piston steam engines. The higher rotation speed made these engines suitable for the propulsion of small and medium-sized fast boats and to produce electricity, thanks to the direct and more efficiently driving connection to electric generator. For this reason, most of them have been produced for stationary use and are equipped with an automatic centrifugal speed regulator. Although this type of engine was produced in large quantities up to the 1920s, only a few examples have survived to this day. The original crankcase of the engine on display indicates its use in the industrial sector to produce electricity.

Click here to listen to the audioguide on izi.TRAVEL

Used in factories and workshops to drive an electric generator.