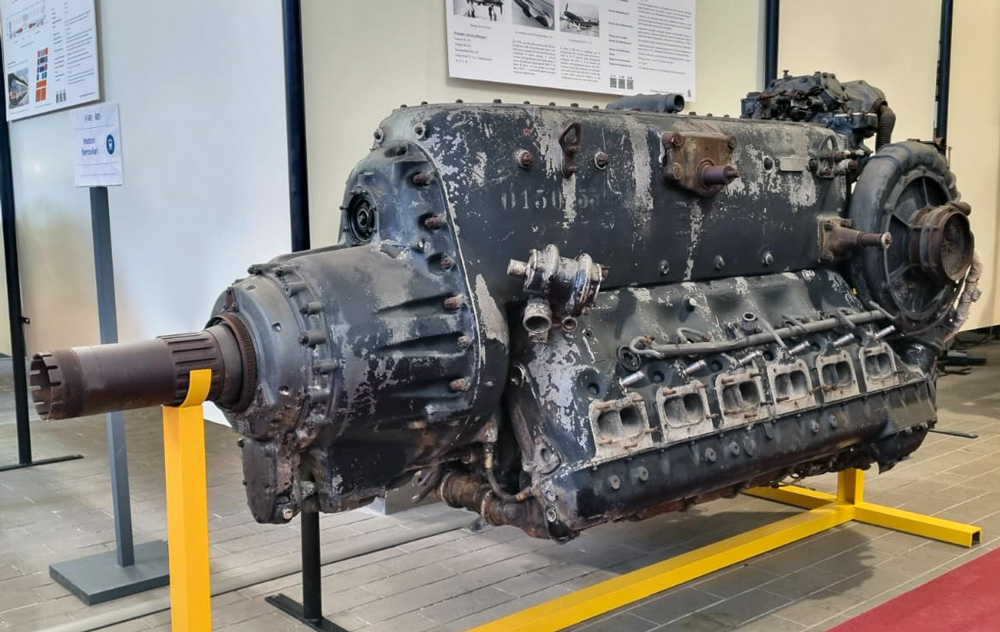

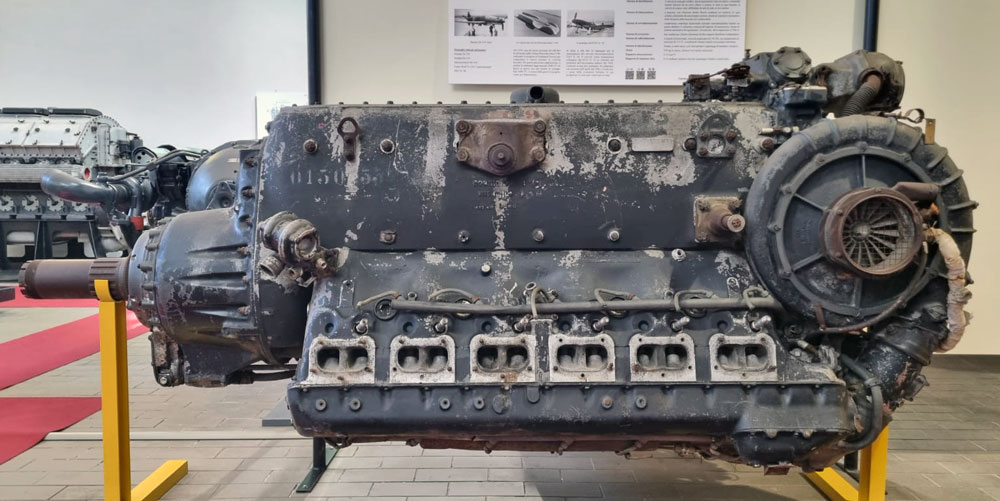

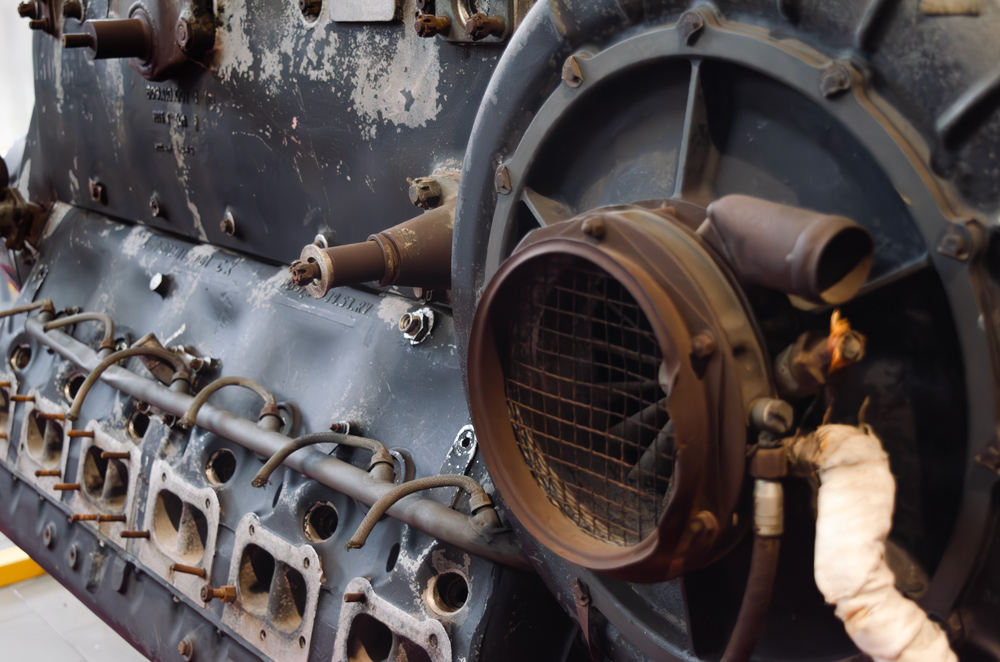

The DB 603 was the largest displacement aircraft engine produced in series by Daimler-Benz during the Second World War. Its original design dates back to the second half of the 1930s and it was developed from the smaller DB 601, maintaining the same inverted V-12 cylinder layout while introducing several modifications, the most significant of which was the substantial increase in total displacement from 33.9 litres to 44.5 litres. Series production began only in 1941, and 36 different versions of the engine had been developed, some featured specific adjustments for high-octane fuels or various modifications for specific applications, while others were equipped with new supercharging systems but remained at experimental stage. A total of 8758 units were produced until 1945, powering various aircraft such as the Messerschmitt Me 410, Heinkel He 219, and Dornier Do 335.

In 1939, one of the early prototypes of the DB 603 was used in the six-wheeled vehicle Mercedes-Benz T 80, designed by Ferdinand Porsche with the aim of setting a new land speed record. For this particular application, the engine was improved to reach 2800 hp on the test bench, with a potential development estimated up to 3500 hp. Due to the Second World War, the project was then abandoned.

In Italy, the DB 603 was specifically used for the development of the FIAT G. 56 fighter aircraft, upon a request of the German Ministry of Aviation in 1943. Strictly derived from the FIAT G. 55 model, only two G. 56 were built, and only one was successfully tested in April 1944 in Turin. Due to the course of the war, the aircraft never undergone into series production.

Click here to listen to the audioguide on izi.TRAVEL

Dornier Do 335

Heinkel He 219

Messerschmitt Me 410

Focke-Wulf Ta 152 C (experimental)

FIAT G. 56

|

|

|